Home / News / Industry news

Industry news

Jan 10,2026

By:Shinging

The Nameless Hero of Industrial Safety

Imagine: a thriving manufacturing plant. The machine rotates, the conveyor belt moves, and the workers focus on their tasks. Suddenly, a surge of electricity hit. Without warning, there is a risk of damage to the equipment, and safety hazards are imminent. Entering the enclosure of the circuit breaker cabinet - a silent guard against electrical chaos.

For business professionals supervising industrial facilities, understanding the role of these Circuit breaker cabinet Enclosures is not just technical terminology. This is about protecting assets, ensuring normal operation time, and protecting lives. In this article, we will delve into why every industrial device requires top-level Circuit breaker cabinet Enclosures, supported by 17 years of expertise from Shinging Technology Co., Ltd., a leader in metal manufacturing solutions.

What is the outer enclosure of the Circuit breaker cabinet Enclosure?

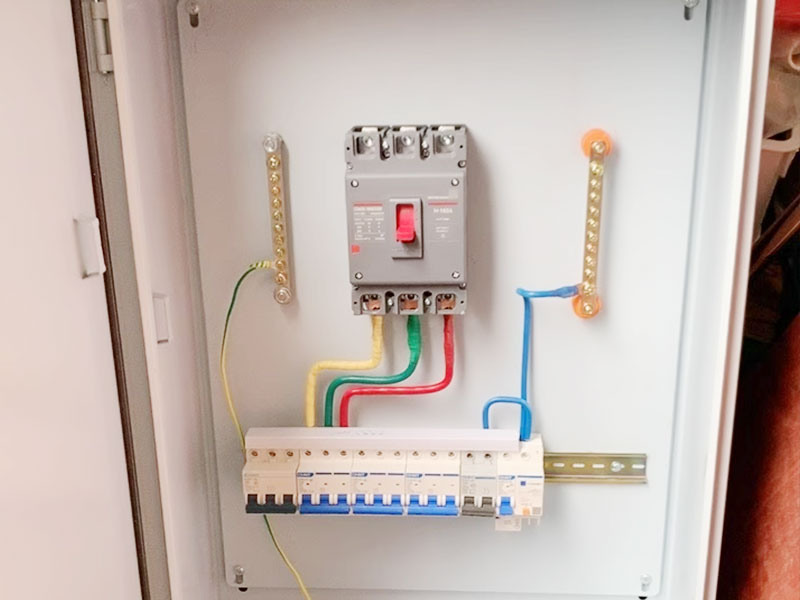

The enclosure of a circuit breaker cabinet is a protective enclosure designed to accommodate circuit breakers, switches, and electrical components. Its main purpose? Protect these critical components from environmental damage (dust, moisture, chemicals), while organizing wiring and preventing accidental contact.

Consider it as a fortress of the electrical system. Without it, circuit breakers would be susceptible to physical shocks, corrosion, and even tampering - all of which are the root causes of disasters.

Inside the Circuit breaker cabinet Enclosure, you usually find circuit breakers that automatically cut off power when overloaded or short circuited. Busbars conduct electricity between components. Safe connection of wiring terminals and input/output cables.

Grounding system, safely redirecting fault current.

Shinging Technology Co., Ltd., Precision machined enclosure, made of durable materials such as stainless steel.

Why is quality important? Because the risk is high.

To prevent electrical fires and electric shock, industrial facilities are high-risk areas. Circuit breaker failure or exposed wires may cause fires or electric shock to workers. The sturdy enclosure acts as a barrier, accommodating sparks and preventing accidental contact.

Example: In 2024, a food processing plant avoided a catastrophic fire because the casing built by their Shinging Technology had a short circuit, giving technicians time to react.

To avoid fines and shutdowns, OSHA, NEMA, and IEEE have established strict standards for electrical enclosures. Failure to comply with regulations may result in significant fines or work stoppages. High quality Circuit breaker cabinet Enclosures meet these benchmarks to ensure the legal operation of your facility. Regularly review your enclosure according to standards such as NEMA 12 (dustproof, oil proof) or IP65 (waterproof and dustproof).

The lifespan and cost-effectiveness of inexpensive enclosures can corrode, crack, or fail under pressure. Investing in advanced cabinets can reduce replacement costs and downtime. Shinging Technology Co., Ltd., The enclosure was built with 17 years of expertise in metal processing and lasted for several decades.

Compared to facilities using high-quality casings, facilities using low-grade casings have a maintenance cost three times higher.

Shinging Technology Co., Ltd., Advantage: 17 years of professional experience

Customized solutions tailored to unique needs

All industrial facilities are the same. Shinging Technology Co., Ltd., Provide customized enclosures according to customer specifications or professional drawings. Whether you need stainless steel for corrosive environments or die-casting for compact designs, they can meet your needs.

Case study: A chemical plant requires an acid resistant smoke resistant enclosure. Shinging Technology Co., Ltd., Designed a 316 stainless steel cabinet with airtight sealing, which extended the lifespan of the equipment by 40%.

End to end manufacturing capability

Shinging Technology handles every step internally, from metal stamping to electrical assembly. This vertical integration ensures quality control and faster turnaround time.

The services provided include stainless steel manufacturing, sheet metal processing, die-casting and injection molding, wiring, and electrical assembly.

Good performance record

Shinging Technology's casing has customers in the automotive, energy, and manufacturing industries, with a failure free rate of 99.8%. Their Circuit breaker cabinet Enclosures are not just boxes - they are designed for reliability.

Common pitfalls to avoid when choosing a cabinet

1. Neglecting environmental factors

Factories in humid coastal areas require different casings than those in dry deserts. Factors such as temperature, humidity, and chemical substances determine the choice of materials (such as aluminum and steel). Therefore, conduct an environmental audit before selecting a cabinet.

2. Underestimating space requirements

Inserting too many circuit breakers into a small enclosure can cause overheating. Ensure proper ventilation and spacing. According to empirical rules, allocate 20% more space than the current demand to accommodate future expansion.

3. Overlooking accessibility

Technicians need convenient maintenance. A housing with hinged doors or detachable panels can save maintenance time.

For design hackers, it is necessary to choose a Circuit breaker cabinet Enclosure with quick release locks and label compartments.

Future Verification of Facilities: Trends in enclosure Design

Intelligent enclosure: IoT integration

The future is interconnected. The intelligent enclosure now includes sensors for real-time monitoring of temperature, humidity, and circuit breaker status. When the conditions exceed the security threshold, Shinging Technology's IoT enclosure will issue an alert to the maintenance team through the application.

sustainability

Environmentally friendly materials - With the focus on ESG goals, manufacturers are shifting towards recyclable materials and energy-efficient designs. Shinging Technology's "GreenLine" enclosure uses 50% recycled aluminum without compromising strength.

Scalable modular design

With the development of facilities, fences should adapt. Modular design allows seamless addition or upgrading of components. Choose a Circuit breaker cabinet Enclosure with standardized installation mode for easy modification.

Investing in protection, not just products

The enclosure of a circuit breaker cabinet is not just an accessory, it is the backbone of electrical infrastructure. By prioritizing quality, customization, and future preparation, you can protect assets, comply with regulations, and ensure operational continuity.

For business professionals, the choice is clear: partnering with manufacturers like Shinging Technology Co., Ltd., whose 17 years of metalworking experience translate into durable enclosures. Don't wait for a disaster to occur - take action now and strengthen the electrical heart of your facilities.

Are you ready to upgrade your cabinet? Contact the limited company for free consultation today. Let their experts design a solution based on your needs - because compromise is impossible in electrical safety.

Water treatment facilities are the unsung heroes of modern civilization, ensuring that millions of people have access to clean and safe water every da...

Jan 21,2026 / Industry news

Driven by digital transformation, the industrial landscape is undergoing earth shattering changes. The core of this revolution is the integration of I...

Jan 18,2026 / Industry news

In the era of Industry 4.0, sustainable development has shifted from a buzzword to a business imperative. As manufacturers strive to reduce their envi...

Jan 18,2026 / Industry newsOnline

Provider of Complete Metal Manufacturing Solutions

+86 18939857433

1188 Jiu Ye Road, Shanghai, China

11561 N Lamar Blvd,Austin,Texas,United States of America,78753

Gyeongin-ro 56-gil 8, ,3F jjbeauty,Guro-gu,Seoul,Guro-gu,Seoul,Republic of Korea

Top

Copyright © 2025 Shinging Technology Co., Ltd.,

Power By Bontop