Home / News / Industry news

Industry news

Dec 16,2025

By:Shinging

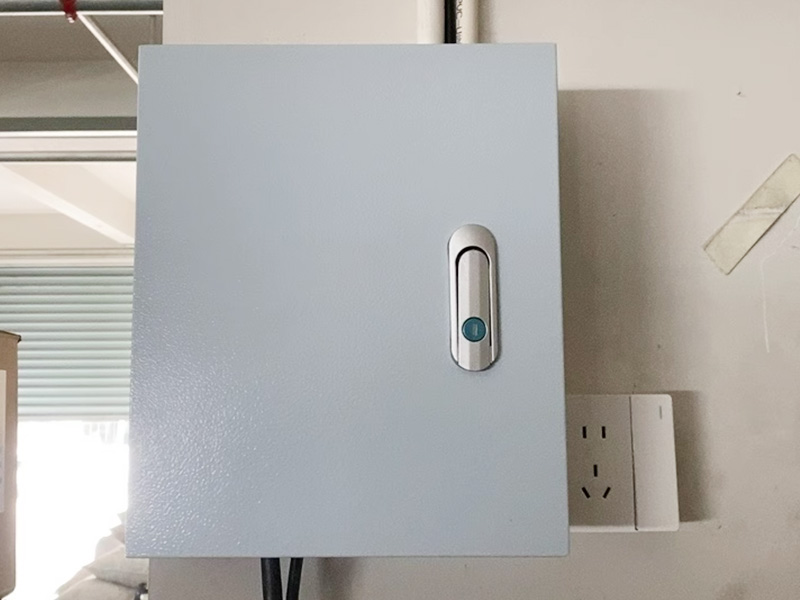

In industrial infrastructure, selecting enclosure materials for Power distribution cabinet Enclosure is a crucial choice influencing durability, cost efficiency, and operational dependability. Business executives tasked with choosing the Power distribution cabinet Enclosure must consider the benefits of steel and aluminum, which lead the industry. When buying a Power distribution cabinet Enclosure, it's essential to make educated choices considering your usage conditions, durability, cost, and additional factors. Shinging Technology Co., Ltd. is a producer with 17 years of expertise in metal manufacturing solutions, including stainless steel production, metal stamping, and electrical assembly. The organization possesses a profound comprehension of how choosing materials aligns with particular project needs.

This piece will emphasize the materials, expenses, and longevity of power distribution cabinet enclosures, enabling you to grasp the industry's status.

The key factors affecting the selection of the Power distribution cabinet Enclosure are durability, corrosion resistance, thermal conductivity, heat dissipation, cost, manufacturing flexibility, and customization

1.What is the difference between durable and corrosion-resistant steel electrical boxes and aluminum electrical boxes?

From the perspective of strength, steel materials have high tensile strength characteristics, making them an ideal choice for strong protection to prevent physical impact or intentional damage. For example, the elasticity advantage of steel has a good effect on outdoor substations in busy traffic areas. Aluminum is mostly designed for lightweight, with a lower density (2.7 g/cm ³, while steel has a density of 7.85 g/cm ³), which greatly reduces its weight and makes installation and transportation easier than steel. For example, an aluminum Power distribution cabinet Enclosure system consisting of 10 units weighs 65% less than a steel Power distribution cabinet Enclosurel system.

From the perspective of corrosiveness, if the steel electrical box is not properly treated (such as galvanized or powder coated), the steel is prone to rusting, especially in humid or coastal climate conditions. Shinging found in a study published in the International Journal of Materials Science in 2024 that untreated steel shells degrade 40% faster than aluminum in saltwater environments. However, aluminum forms a protective oxide layer when exposed to air, thus possessing inherent corrosion resistance. This characteristic is particularly advantageous in marine or chemical processing applications.

From the perspective of corrosion resistance, aluminum forms a protective oxide layer when exposed to air, which has inherent corrosion resistance. This characteristic is advantageous for marine or chemical processing applications.

From the perspective of lightweight design, aluminum has a lower density of 2.7 g/cm ³, while steel has a density of 7.85 g/cm ³, reducing structural loads and making installation and transportation easier. For example, an aluminum Power distribution cabinet Enclosurel system consisting of 10 units weighs 65% less than a steel Power distribution cabinet Enclosure system.

2.From the perspective of thermal conductivity and heat dissipation, steel has a poor heat transfer of 50 W/m · K and low thermal conductivity. Additional cooling systems such as fans or radiators are required in high-temperature environments. Shinging Technology Co., Ltd., A case study shows that steel enclosures in desert areas require 30% more cooling infrastructure than aluminum alternatives.

The excellent heat dissipation performance of aluminum is 237 W/m · K, which enables it to naturally regulate the internal temperature and has high thermal conductivity. This reduces energy costs and extends the lifespan of enclosed electrical components. For example, in a pilot project in 2025, the aluminum Power distribution cabinet Enclosure of data centers reduced cooling costs by 22%.

3.From a cost analysis perspective, what is the difference between the initial cost and lifecycle cost of aluminum and steel materials

Steel enclosures materials have lower costs, and the price per kilogram of steel is usually cheaper than aluminum, making it attractive for budget conscious projects. However, the steel Power distribution cabinet Enclosure requires maintenance in the later stage, usually repainted every 5-7 years, and potential downtime caused by corrosion related failures can result in hidden costs.

Aluminum enclosures have higher initial costs, but the premium of aluminum is offset by its longer lifespan. A 10-year lifecycle analysis by Materials Review shows that due to reduced maintenance and replacement needs, the total cost of aluminum enclosures is 18% lower than that of steel enclosures.

From the perspective of manufacturing flexibility and customization, steel enclosures are manufactured with precision, and the ductility of steel allows for the formation of complex shapes through stamping or die casting. Shinging Technology Co., Ltd., Professional knowledge in sheet metal manufacturing ensures that the enclosure meets accurate specifications and has dust and water resistance levels of IP65 to IP68.

The aluminumenclosurel is easy to process, and the flexibility of aluminum simplifies processes such as CNC milling, achieving rapid prototyping. Using Shinging's injection molding service, we designed and produced a customized aluminum Power distribution cabinet Enclosure for a renewable energy project within 14 days.

What are the applications and case studies in the real world?

Case Study 1: Steel in a High Safety Environment

Due to strict security requirements, a financial institution in New York has chosen steel enclosures for its data center. These Power distribution cabinet Enclosures are manufactured by Shinging Technology Co., Ltd. with reinforced frames and biometric locks, and have withstood simulated intrusion attempts without structural compromise.

Case Study 2: Aluminum in Offshore Wind Farms

A offshore wind power operator in Beihai has chosen an aluminum Power distribution cabinet Enclosure to accommodate the distribution system. The corros ion resistance of this material will reduce the inspection frequency from once a month to once every two years, saving $120000 in operating costs annually.

Business professionals can refer to insights

From the perspective of evaluating environmental conditions, priority should be given to aluminum in coastal or high humidity areas; For inland areas with low corrosion, steel can be chosen.

The selection of total cost of ownership should consider the maintenance, energy, and replacement costs within the lifespan of the cabinet.

If customized services are required, please collaborate with Shinging Technology Co., Ltd., a manufacturer, to optimize the design for specific use cases (such as explosion-proof enclosures in the oil and gas industry).

The choice of the enclosure of the distribution cabinet between steel and aluminum depends on the specific priority of the project. Steel performs well in cost sensitive and high safety scenarios, while aluminum dominates in environments that are prone to corrosion or have high thermal requirements. By collaborating with experienced manufacturers such as Shinging Technology Co., Ltd., which provides end-to-end solutions from stainless steel manufacturing to electrical assembly, our company can ensure that their enclosures meet technical, budget, and operational requirements.

Water treatment facilities are the unsung heroes of modern civilization, ensuring that millions of people have access to clean and safe water every da...

Jan 21,2026 / Industry news

Driven by digital transformation, the industrial landscape is undergoing earth shattering changes. The core of this revolution is the integration of I...

Jan 18,2026 / Industry news

In the era of Industry 4.0, sustainable development has shifted from a buzzword to a business imperative. As manufacturers strive to reduce their envi...

Jan 18,2026 / Industry newsOnline

Provider of Complete Metal Manufacturing Solutions

+86 18939857433

1188 Jiu Ye Road, Shanghai, China

11561 N Lamar Blvd,Austin,Texas,United States of America,78753

Gyeongin-ro 56-gil 8, ,3F jjbeauty,Guro-gu,Seoul,Guro-gu,Seoul,Republic of Korea

Top

Copyright © 2025 Shinging Technology Co., Ltd.,

Power By Bontop