Home / News / Industry news

Industry news

Nov 25,2025

By:Shinging

In industrial and commercial environments, electrical junction box enclosures are important protective tools for electrical systems. These enclosures protect the wiring connections from environmental hazards, physical damage, and unauthorized access, while ensuring that the equipment complies with safety regulations. These contents are very suitable for beginners in electrical equipment or industrial industries to understand the required electrical enclosures, as well as for professional electrical equipment business personnel to understand the safety standards for managing these cabinets. This is crucial for reducing risks, avoiding legal liabilities, and maintaining operational efficiency.

This article provides comprehensive guidance on the safety standards for electrical junction box enclosures, including the importance of electrical junction boxes, key regulatory frameworks, design considerations, and practical applications. In addition, we also introduced how a manufacturer limited company with 17 years of professional knowledge in the field of metal manufacturing can provide customized solutions to meet strict safety requirements. I hope it will be helpful for you to choose a suitable cabinet.

What is the significance of safety standards?

In industrial, commercial, and residential environments, electrical junction box enclosures provide more than just protection; If the purchased electrical enclosure does not meet the certification requirements of the electrical enclosure, it may result in penalties for purchasing the enclosure, project delays, and potential lawsuits against the company, especially in industries such as construction, manufacturing, and energy. These shells have been carefully customized to withstand specific extreme environments and operating conditions in application locations, while complying with safety regulations to ensure hazard protection, regulatory compliance, lifespan, cost-effectiveness, worker safety, and other standards. This is particularly evident in how the casing protects electrical connections from dust, moisture, chemicals, and impacts, thereby minimizing the possibility of short circuits, fires, or equipment failures. Therefore, it is very important for buyers to choose manufacturers with certification capabilities.Premium casings lower maintenance expenses and prolong the durability of electrical systems. Correctly rated enclosures reduce interaction with live electrical parts and shield personnel from electric shocks or burns.

Common key safety standards and certifications consist of NEMA rating certification, IP waterproof rating certification, UL certification, and IEC standard certification.

What does NEMA certification signify?

NEMA standard certification categorizes electrical junction box enclosures according to their capacity to safeguard against environmental threats. Frequent ratings comprise NEMA 1, NEMA 3R, NEMA 4X, and NEMA 12. NEMA 1 is typically used indoors; it shields against dust and light splashes but lacks waterproof features. NEMA 3R is waterproof against rain and appropriate for outdoor applications, yet has restricted moisture exposure and is classified as primary waterproofing. NEMA 4X is capable of enduring watertight conditions and is resistant to corrosion, making it suitable for tough settings like food processing facilities or coastal regions. NEMA 12 is resistant to dust and droplets, suitable for industrial settings with airborne contaminants.

Factories with heavy dust exposure ought to select NEMA 12 enclosures to avoid obstruction of electrical components.

What is IP level certification mean?

The International Electrotechnical Commission (IEC) defines IP level certification to indicate the safeguarding against solids and liquids. The standard format is IPXY, where X indicates a solid protection rating of 0-6;the level 5 signifies protection against dust. Y signifies liquid protection across levels 0-8, the level 6 designated for robust water spraying.

Outdoor Electrical junction box Enclosure need a minimum of IP65 rating against dust and low voltage water spray during rainy weather.

What does UL certification mean?

UL certification is utilized to confirm that the casing adheres to rigorous safety standards. Frequent UL standards consist of UL 50 and UL 50E. UL 50 pertains to the housing of all electrical devices. UL 50E primarily focuses on Electrical junction box Enclosures of types 3R, 4, 4X, and 12.

Always check the UL certification label prior to buying the Electrical junction box Enclosure to confirm compliance.

What do IEC standards entail?

The IP certification is globally defined by the IEC 60529 standard, while the IEC 62208 outlines the criteria for the Electrical junction box Enclosure of low-voltage switchgear and control equipment.

What are the considerations for safety design?

The main considerations include materials, gasket and sealing quality, door locks, ventilation, and thermal management.

From the perspective of material selection, as personnel in the electrical equipment enclosure business, the materials for electrical junction box enclosures include stainless steel, aluminum, or polycarbonate. The specific choice of material depends on the usage environment. Stainless steel is suitable for corrosive environments, such as chemical plants. Aluminum material is lightweight and only suitable for indoor applications. Polycarbonate is non-conductive and can be used in low-pressure environments.

Shinging Technology Co., Ltd., Stainless steel manufacturing and metal stamping ensure that the casing can withstand extreme conditions while maintaining structural integrity.

Considering the selection of gaskets and sealing quality, high-quality gaskets can prevent moisture from entering. Silicone or chloroprene rubber seals are common in NEMA 4X/IP65 Electrical junction box Enclosure.

From the perspective of door lock structure selection, tamper proof locks are crucial in public or hazardous areas to prevent unauthorized access.

From the perspective of ventilation and thermal management, Electrical junction box Enclosures that accommodate heating components require ventilation openings or cooling systems to prevent overheating.

Factors to consider from practical application scenarios include industrial automation, renewable energy, medical facilities, etc.

Industrial automation In automobile factories, the NEMA 4X Electrical junction box Enclosure protects the robot controller from cold spray and metal chips.

Renewable energy mainly includes outdoor inverter Electrical junction box Enclosure with IP67 protection level for solar power plants, ensuring their durability against rain and dust.

Medical facilities mainly deploy NEMA 12 Electrical junction box Enclosure in hospital sterile environments to prevent contamination of critical medical equipment.

Shinging Technology: Your Security Partner

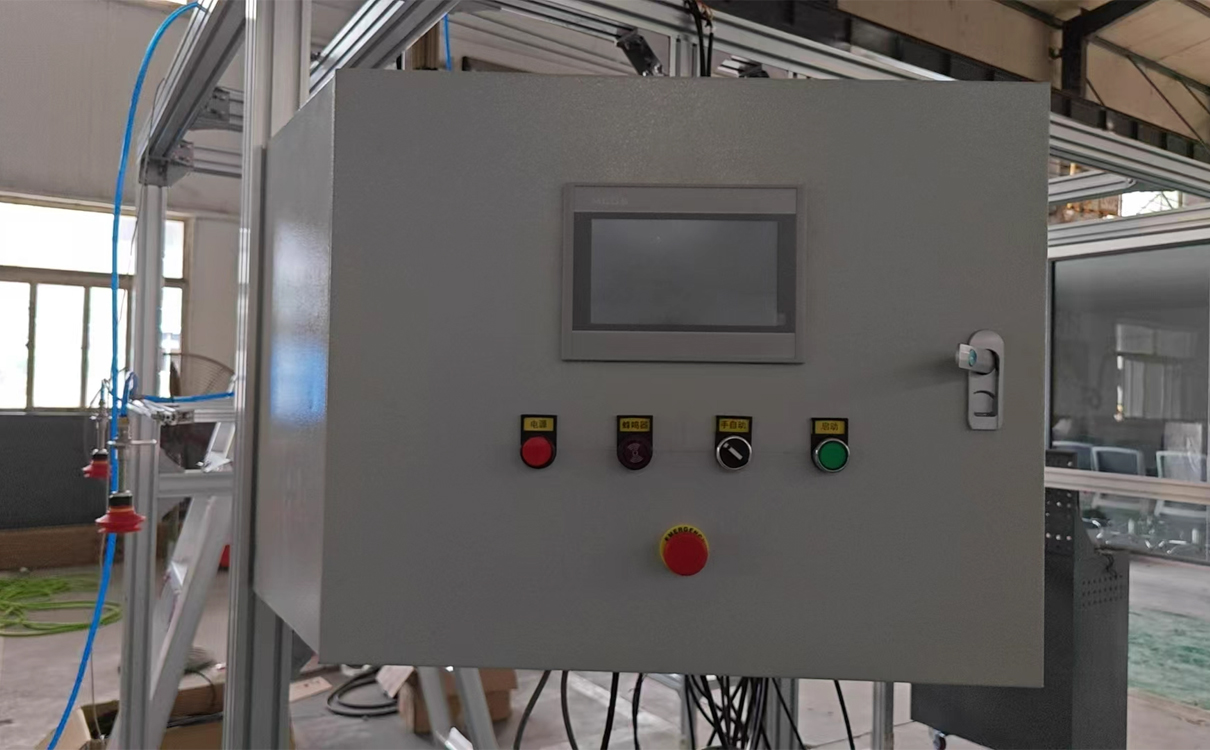

Shinging Technology has 17 years of experience in providing comprehensive metal manufacturing solutions to meet the needs of Electrical junction box Enclosure. From stainless steel enclosure to die cast aluminum enclosure, we produce components according to your drawings or specifications. Ensure that all products comply with NEMA, IP, and UL standards and provide certification documents. Our capabilities include sheet metal manufacturing, electrical assembly, and injection molding, ensuring precision and scalability.

Customer case: One of our clients in the oil and gas industry requested that offshore platforms use NEMA 4X Electrical junction box Enclosures. Shinging Technology offers a corrosion-resistant stainless steel enclosure with IP68 rating, reducing downtime by 40%.

What are the typical mistakes and precautions to consider when buying Electrical junction box Enclosure?

The Electrical junction box Enclosure's rated value is insufficient, and employing NEMA 1 enclosures outside can lead to swift deterioration. Ignoring certification can lead to non-UL certified products not passing inspection or leading to accidents. Ignoring thermal design, even in compliant Electrical junction box Enclosures, inadequate ventilation may result in component failure.

Consequently, for business professionals valuing reliability, compliance, and cost-efficiency, the safety regulations for Electrical junction box Enclosures are essential. Complying with NEMA, IP, and UL standards and partnering with knowledgeable manufacturers like Shinging Technology helps guarantee the safe operation of your electrical system in any setting.

Reach out to Shinging Technology right away to talk about your Electrical junction box Enclosure needs and get complimentary advice on enhancing security and efficiency.

Water treatment facilities are the unsung heroes of modern civilization, ensuring that millions of people have access to clean and safe water every da...

Jan 21,2026 / Industry news

Driven by digital transformation, the industrial landscape is undergoing earth shattering changes. The core of this revolution is the integration of I...

Jan 18,2026 / Industry news

In the era of Industry 4.0, sustainable development has shifted from a buzzword to a business imperative. As manufacturers strive to reduce their envi...

Jan 18,2026 / Industry newsOnline

Provider of Complete Metal Manufacturing Solutions

+86 18939857433

1188 Jiu Ye Road, Shanghai, China

11561 N Lamar Blvd,Austin,Texas,United States of America,78753

Gyeongin-ro 56-gil 8, ,3F jjbeauty,Guro-gu,Seoul,Guro-gu,Seoul,Republic of Korea

Top

Copyright © 2025 Shinging Technology Co., Ltd.,

Power By Bontop